Scie à fil diamanté automatique avec platine d'angle électrique

1. La scie à fil diamantée électrique à angle est conçue et développée dans notre propre usine, avec une précision garantie. Nous disposons également d'une équipe de professionnels pour répondre à toutes vos questions sur nos produits.

2. Les scies à fil diamanté à angle électrique conviennent à la découpe de précision d'échantillons de matériaux cassants et peuvent trancher et couper les matériaux.

3. Notre scie à fil diamantée à angle électrique peut couper une variété de matériaux, tels que la céramique, les cristaux, etc., et a une large gamme d'applicabilité.

- Shenyang Kejing

- Shenyang, Chine

- 22 jours ouvrables

- 50 ensembles

- information

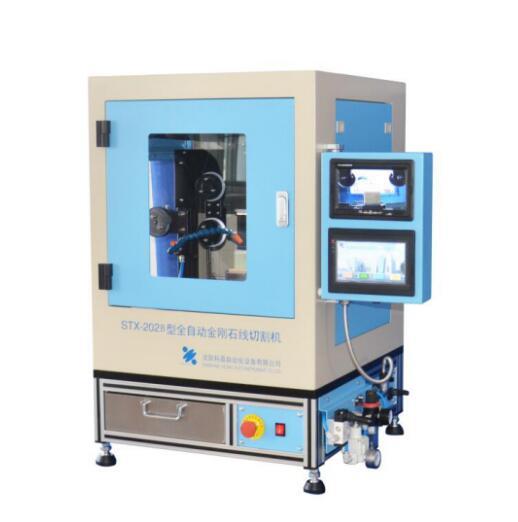

Présentation de la scie à fil diamanté à angle électrique :

La scie à fil électrique de précision STX-203 est spécialement conçue pour les chercheurs en matériaux. Elle permet la découpe précise d'échantillons de matériaux fragiles. Elle permet de trancher et de couper des matériaux tels que la céramique, les cristaux, le verre, les métaux, les roches, les matériaux thermoélectriques, les matériaux optiques infrarouges, les matériaux composites et les matériaux biomédicaux.

Paramètres techniques

Nom du produit | Scie à fil diamanté entièrement automatique STX-203 | |

Modèle de produit | STX-203 | |

| Conditions d'installation | 1. Température et humidité : 10-85 % HR (à 25 ℃ sans condensation) Température : 0-45 ℃. 2. Il n’y a pas de sources de tremblement de terre fortes ni de gaz corrosifs autour de l’équipement. 3. Liquide de refroidissement : nécessaire (il est recommandé d'utiliser --- huile de coupe). 4. Alimentation : monophasé : AC220V 50Hz 5. Source d'air (air comprimé) : ≥ 0,6 Mpa. 6. Taille de l'établi : 800×700×500 mm sont recommandés, avec une capacité de charge de 150 kg ou plus (une table en ciment solide est préférée) 7. Dispositif de ventilation : aucune exigence particulière. | |

Principaux paramètres | 1. Interface d'alimentation : AC220 50 Hz 10 A 2. Puissance totale : 120 W (hors compresseur d'air) 3. Structure du corps principal : cadre en alliage d'aluminium, coque fermée en tôle 4. Longueur du fil diamanté (m) : ≤ 45 m 5. Diamètre du fil diamanté (mm) : ≤ 0,45 mm 6. Méthode de tension du fil diamanté : tension pneumatique réglable 7. Méthode de rotation de la broche de coupe : rotation alternative 8. Vitesse de broche : 2 à 300 tr/min réglable 9.Vitesse de coupe : 0,05–40 mm/min 10.Vitesse de retour : 1–40 mm/min 11. Course effective de l'axe Z : ≤ 60 mm 12. Course effective de l'axe Y : 0,01 à 50 mm 13. Angle de rotation de la table : électrique, horizontal 0-360° 14. Angle d'inclinaison de la table : électrique, ±10° 15. Espacement limite supérieur entre les côtés intérieurs des deux roues de guidage : 96 mm 16. Diamètre et longueur de la pièce à usiner : ≤Φ50×50 mm 17. Taille du bloc d'échantillon (longueur×largeur×hauteur) : 80 mm×51 mm×12 mm 18. Épaisseur de coupe (profondeur) : valeur effective ≤ 50 mm 19. Mode de contrôle : programmateur PLC de contrôle intégré + écran tactile de 7 pouces 20. Surveillance vidéo de la zone de coupe : écran 7 pouces | |

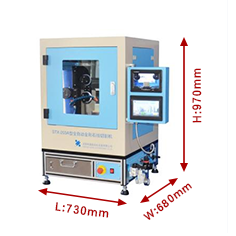

Spécification du produit | ·Dimensions du contour (longueur × largeur × hauteur) : 730 mm × 680 mm × 970 mm ·Poids net : environ 130 kg |

|

| Fonctions et applications | 1. Matériaux céramiques : céramiques d'oxyde d'aluminium, céramiques d'oxyde de zinc, céramiques d'oxyde de zirconium, céramiques cibles, céramiques en nid d'abeille, céramiques semi-conductrices, céramiques conductrices, céramiques non conductrices, etc. 2. Matériau cristallin : graphite, cristal de silicium (polysilicium solaire, silicium monocristallin), saphir, cristal d'oxyde d'aluminium, cristal de verre infrarouge, cristal d'oxyde d'aluminium, cristal de carbure de silicium, cristal d'iodure de césium, etc. 3. Matériaux en verre : verre chalcogénure, verre optique, verre de quartz, verre infrarouge, tube de verre, etc. 4. Matériaux métalliques : fer, aluminium, cuivre, alliage de titane, alliage de magnésium et autres métaux et alliages, métaux non ferreux (sulfure de zinc, ferrite), etc. 5. Matériaux composites : panneau PVC, matériau composite en fibre de carbone, matériau composite en fibre de verre, etc. 6. Matériau de la roche : découpe de précision de roche naturelle, jade, météorite, jadéite/émeraude, agate, etc. Découpe de précision de divers matériaux de grande valeur ; tranches géologiques, tranches géologiques (roches sédimentaires, roches magmatiques, roches métamorphiques, minerai) et autres tranches carrées 7. Matériaux thermoélectriques : tellurure de bismuth, tellurure de plomb, alliage silicium-germanium, etc. 8. Matériaux optiques infrarouges : séléniure de zinc, sulfure de zinc, silicium, germanium et autres cristaux 9. Matériaux biomédicaux : tranches d'échantillons bioplastifiés (organes humains et animaux, sections combinées de tissus mous et durs de la mâchoire, observation d'implants, couronnes et ponts dentaires, dents et autres échantillons histologiques) ; Coupes articulaires orthopédiques de tissus mous et durs (fémoral, hanche, corps vertébral et autres tissus frais et tissus durs, échantillons histologiques osseux avec implants, etc.) ; Tranches de stents cardiovasculaires et cérébrovasculaires, tranches de calculs et autres tranches de tissus médicaux ; … Remarque : les matériaux dont la dureté est inférieure à celle du fil diamanté peuvent être coupés avec précision. | |

Conformité | La certification CE, UL ou CSA est disponible moyennant un coût supplémentaire. | |

Accessoires standard

Non. | nom | quantité | image |

1 | Roue de tension en polyéthylène (PE) | 2 pièces |

|

2 | Roue motrice en polyéthylène (PE) | 2 pièces |

|

3 | Moule de positionnement à 90° pour coupe de 2 pouces | 1 ensemble |  |

4 | Fil de coupe diamanté | 3 rouleaux |

|

5 | Pompe à eau | 1 pièce |  |

6 | Céramique liée à la résine | 2 pièces |

|

7 | Enseigner | 4 pièces |

|

Accessoires en option

Non. | nom | type fonctionnel | image |

1 | Fil de coupe diamanté (Ø0,35, Ø0,42 mm) | (facultatif) |

|

2 | Huile spéciale pour la coupe | (facultatif) |  |

3 | Dispositif de découpe de tranches géologiques | (facultatif) |  |

4 | Plateforme de chauffage série HEATER | (facultatif) |

|

5 | Microscope portable (microscope numérique sans fil 3R) | (facultatif) |  |

6 | (facultatif) |  | |

7 | Radiogoniomètre monocristallin DX-100 | (facultatif) |

|

Garantie

· Garantie limitée d'un an avec assistance à vie (hors pièces rouillées dues à des conditions de stockage inadéquates)

Logistique

À propos de nous

Nos poinçonneuses manuelles pour échantillons cylindriques sont fabriquées avec des matériaux de haute qualité et sont dotées d'équipements durables et performants. Notre entreprise applique également un processus de contrôle qualité strict. Avant que le produit ne quitte l'usine, nos employés effectuent des tests complets pour garantir la précision et la stabilité de la poinçonneuse électrique. Nous disposons également d'un service après-vente professionnel. Pour toute question concernant le produit, notre équipe vous répondra rapidement afin que votre poinçonneuse pour échantillons cylindriques puisse fonctionner de manière stable et durable.