Scie à découper et à découper CNC de précision

1. Notre machine de découpe de laboratoire a une vitesse de coupe rapide et peut répondre à vos différents besoins.

2. Notre machine de découpe de laboratoire est conçue et produite par notre société avec une garantie d'un an.

3. Notre entreprise assure la qualité de ses machines de découpe de laboratoire. Pour toute question, n'hésitez pas à nous contacter.

- Shenyang Kejing

- Shenyang, Chine

- 10 jours ouvrables

- 50 ensembles

- information

Présentation de la machine de découpe de laboratoire :

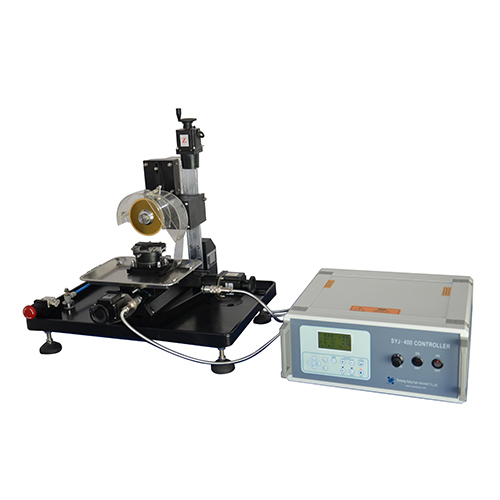

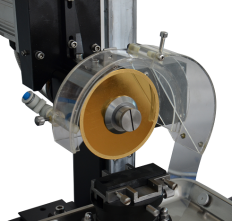

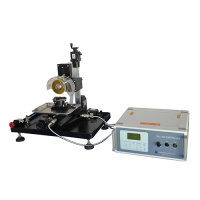

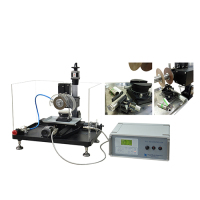

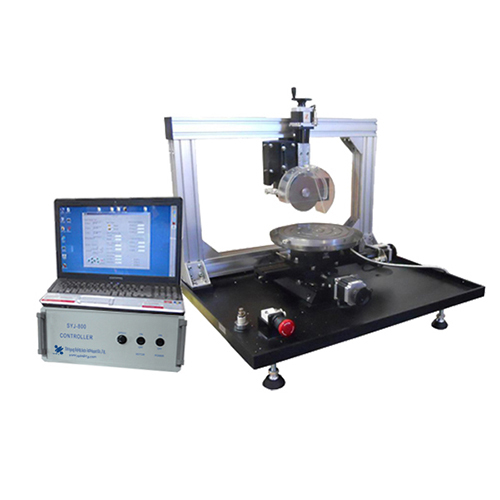

La micro-machine de découpe de laboratoire CNC SYJ-400 est principalement adaptée au découpage, au rainurage et à la découpe de divers matériaux tels que les cristaux, la céramique, le verre, le minerai, le métal, etc. Elle est équipée d'un moteur pas à pas et peut être informatisée avec une précision de positionnement de 0,01 mm. Elle est rotative à 360° et équipée d'un étau à montage transversal (avec matrice de positionnement à 90° pour garantir la précision de la découpe) et d'un mandrin à vide (en option).

Principales caractéristiques descie circulaire à métaux:

Contrôle informatisé, permettant aux utilisateurs de programmer eux-mêmes la découpe des échantillons

Adopter un moteur sans balais à courant alternatif à couple élevé pour entraîner la broche via des poulies à courroie et régler la vitesse de rotation de 0 à 3 000 tr/min via des boutons de régulation de vitesse

Choisir la lame et la pince de lame appropriées en fonction de la taille des échantillons de matériaux

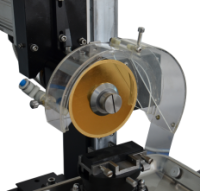

Équipé d'un couvercle de protection contre les éclaboussures et d'un papillon des gaz pour contrôler le débit du liquide de refroidissement

Paramètres techniques de scie circulaire à métaux

Nom du produit | Scie à découper CNC SYJ-400 | |

Modèle de scie circulaire à métaux | SYJ-400 | |

Conditions d'installation de scie circulaire à métaux | 1. Température et humidité : 10-85 % HR (à 25 ℃ sans condensation) Température : 0-45 ℃. 2. Il n'y a pas de source de vibrations fortes ni de gaz corrosif autour de la scie de découpe et de découpage CNC. 3. Alimentation : prise tripolaire standard américaine AC110V 60Hz (machine personnalisée). Prise tripolaire standard nationale AC220V 50Hz. 4. Eau de refroidissement : la scie de découpe et de découpage CNC est équipée d'une entrée et d'une sortie d'eau, et vous devez connecter vous-même l'eau du robinet et les dispositifs de drainage. 5. Source d'air : aucun équipement standard requis. 6. Établi : dimensions 800 mm × 600 mm × 700 mm, capacité de charge supérieure à 50 kg. 7. Dispositif de ventilation : bon environnement de ventilation, aucune exigence particulière en matière de dispositif de ventilation. | |

Principaux paramètres (Spécifications) de la scie circulaire à métaux | 1. Port d'alimentation : AC220V 50Hz. 2. Vitesse de la broche : régulation de vitesse en continu de 0 à 3 000 tr/min. 3. Puissance d'entraînement de la broche : 180 W. 4. Course de la glissière sur l'axe X : 210 mm. 5. Course de la glissière de l'axe Y : 110 mm. 6. Course du chariot de l'axe Z : 90 mm. 7. Profondeur de coupe max : 50 mm. 8. Moteur d'entraînement des axes X/Y/Z : moteur pas à pas de haute précision. 9. Précision de positionnement du moteur pas à pas : 0,01 mm. 10. Angle et erreur de l'établi : 360°±0,5°. 11. Taille du bloc de chargement de la machine de découpage de plaquettes : 80 mm × 25,4 mm. 12. Taille de la lame de scie : Ø100/Ø150 mm × Ø12,7 mm (taille d'installation du diamètre intérieur). 13. Mode de contrôle de l'hôte : Modèle monocarte : panneau de contrôle + ordinateur monocarte. Version informatique : programme informatique (USB) + ordinateur monocarte. | |

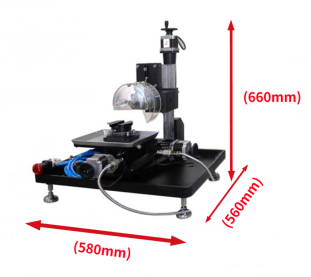

14. Spécifications de la scie de découpe et de découpage CNC : ·Taille : 580 mm × 560 mm × 660 mm ·Poids : ≈39 kg |

| |

Notes sur la machine à découper les gaufrettes : 1. L'alimentation électrique standard de la scie à découper CNC est de 220 V CA 50 Hz. Les paramètres d'alimentation réels sont indiqués sur l'étiquette apposée au dos du produit. 2. La scie à découper et à découper CNC prend en charge un équipement d'alimentation AC110V 60Hz personnalisé. 3. Si vous personnalisez la version informatique de la scie à découper CNC, vous devez utiliser votre propre ordinateur comme hôte de contrôle. La scie à découper CNC est livrée avec un programme d'installation sur disque dur ("U). | ||

Accessoires standard de la scie circulaire à métaux :

Non. | nom | quantité | image |

1 | patins de scie | total 3 ensembles |

|

2 | Serre-joint en croix | 1 ensemble | |

3 | Bloc de charge en aluminium | 2 pièces |

|

4 | Céramique liée à la résine (50×50×10mm) | 2 pièces | |

5 | Lame diamantée entièrement frittée (Ø100 mm × Ø12,7 mm × 0,33 mm) | 1 pièce |

|

6 | Lame diamantée électrolytique Ø100 mm × Ø12,7 mm × 0,5 mm | 2 pièces |

|

7 | Bâton de cire de paraffine | 4 pièces |

|

8 | Housse imperméable | 1 ensemble | |

9 | Lunettes de protection | 1 paire |

|

Accessoires optionnels :

Non. | nom | type fonctionnel | image |

1 | Lame diamantée frittée Edge (Ø100 mm × Ø12,7 mm × 0,33 mm) | (facultatif) |

|

2 | Lame de découpe en diamant fritté | (facultatif) | |

3 | Pompe à vide sans huile | (facultatif) | |

4 | Réservoir de circulation de liquide de refroidissement JXZ-25Y (avec pompe) | (facultatif) | |

5 | plaque chauffante | (facultatif) |  |

Remarques et avertissements :

· Il est recommandé aux clients d'utiliser un liquide de refroidissement anticorrosion pendant le processus de découpe pour éviter la rouille de la vis mère.

· Assurez-vous de nettoyer la machine après chaque utilisation, en particulier nettoyez la vis mère avec du lubrifiant pour vous assurer que les axes X, Y et Z peuvent se déplacer librement sans se bloquer ni rouiller.

Garantie de la machine à découper les gaufrettes :

Garantie limitée d'un an avec assistance à vie (hors pièces rouillées en raison de conditions de stockage inadéquates)

Logistique de la machine de découpage de gaufrettes :

À propos de nous:

Afin de garantir l'intégrité de chaque machine de découpe de wafers reçue par nos clients, nous visons l'excellence en matière de logistique et d'emballage. Nous utilisons des matériaux et des méthodes d'emballage conformes aux normes internationales, associés à une technologie de chargement professionnelle, afin de minimiser les risques liés au transport. Parallèlement, nous collaborons avec de nombreuses entreprises de logistique internationales pour garantir la livraison de nos machines de découpe de wafers aux clients en toute sécurité et dans les délais.